Shaped Forgings, Rings & Bars

Specialist Supplier of tailor-made materials.

Established in 2012 with the purpose of facilitating manufacturers within the Oil & Gas Industry. We supply shaped forgings, rings & bars to OEMs & Subcontract machine shops prepared for their final machining.

We stock a varied range of low alloy & super alloy steels, with our in-house lathe facilities to machine near shape prior to heat treatment or direct shipment.

Our continued successes & recognition within our target industry, have resulted in opportunities in other sectors such as Defence & Pump Industries.

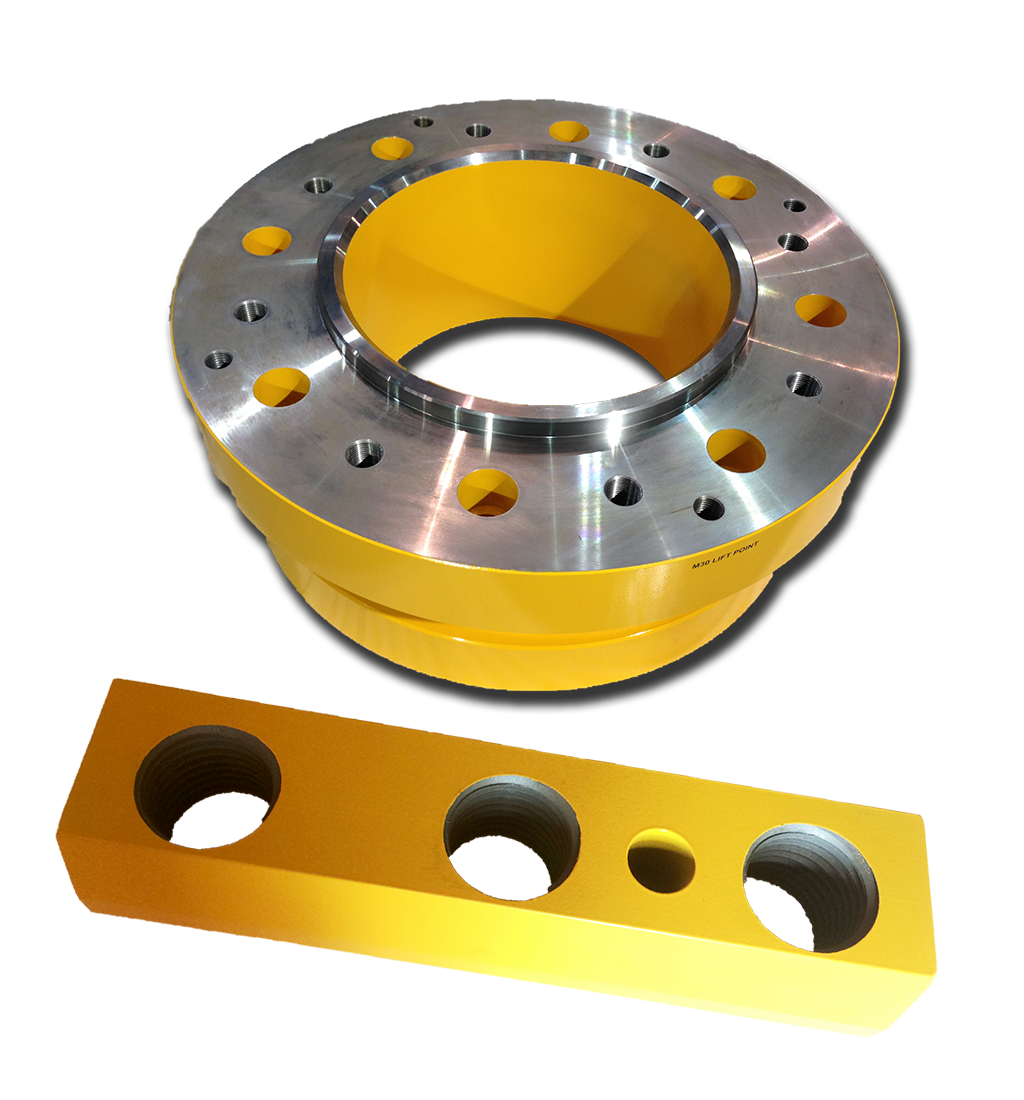

Engineer-shaped forgings represent the pinnacle of metallurgical craftsmanship, meticulously crafted to meet stringent engineering specifications. These forgings offer unparalleled strength, durability, and reliability across a multitude of industries, including aerospace, automotive, and heavy machinery. Through advanced forging techniques, engineer-shaped forgings exhibit exceptional material properties and dimensional accuracy, making them indispensable components in critical applications where precision and performance are non-negotiable.

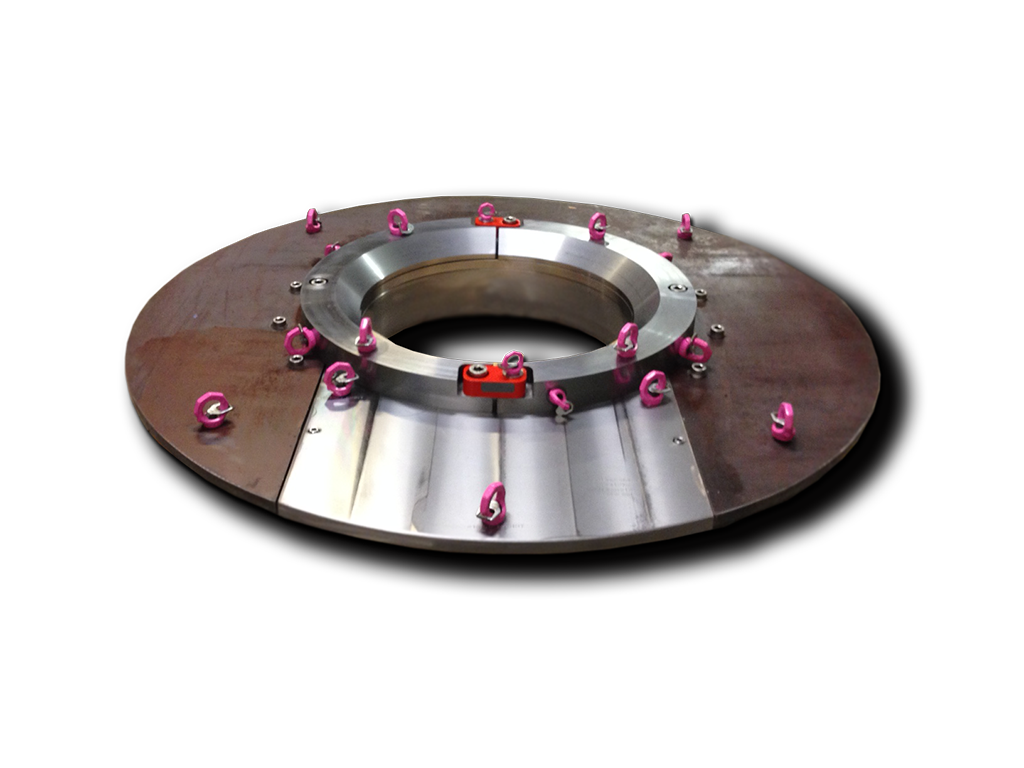

Engineer-shaped forged rings are meticulously crafted metal components designed to meet precise engineering specifications, offering exceptional strength, durability, and reliability for a diverse range of applications across industries such as aerospace, automotive, oil and gas, and manufacturing. These rings are meticulously forged using advanced techniques to ensure uniformity, consistency, and optimal performance, making them essential components in critical machinery and structures where precision and reliability are paramount.

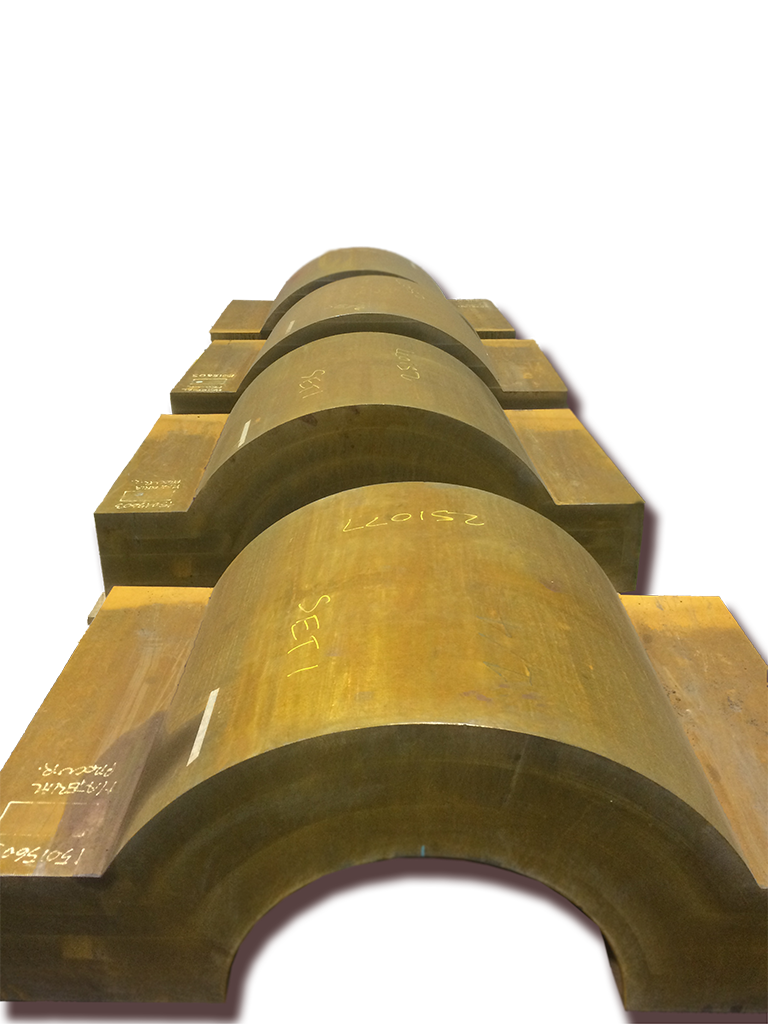

Engineered forged bars exemplify the fusion of precision engineering and metallurgical expertise. These bars are meticulously crafted through forging processes, resulting in superior strength, resilience, and dimensional accuracy. Engineered forged bars find application in demanding industries such as aerospace, defense, and oil and gas, where reliability and performance are paramount. Through careful design and manufacturing, these bars provide exceptional mechanical properties, ensuring their effectiveness in critical applications requiring robust and durable components.

Heat Treatment has long been recognised as one of the essential weapons in the metallurgist's armoury and is capable of radically changing the structure of metal.

Heat treatment is used either to prepare a material for further processing (machining, forging, pressing, spinning, etc.) or to add a property such as surface hardness to improve a product's performance in service.

Extensive in-house machining capability for proof or finish machined forgings Our in-house machining gives us the capability to offer proof or finished machined forgings to customer requirements. We can carry out a full range of complex or simple machining operations on our forged components.

The benefits of our combined drop forging and machining services are appreciated by customers who want to obtain complete parts from one source, improving communication, quality, lead time and overall cost. Machining Capacity

Testing engineered forged metals is a critical process that ensures the reliability, durability, and performance of these components across various industries. Through meticulous examination, including destructive and non-destructive methods such as tensile testing, hardness testing, ultrasonic testing, and metallurgical analysis, the integrity of engineered forged metals is thoroughly evaluated. This rigorous testing regime guarantees that the materials meet stringent quality standards and engineering specifications, ultimately providing confidence in their suitability for demanding applications in aerospace, automotive, energy, and other sectors where safety and reliability are paramount.

LOW ALLOYS

We supply Shaped Forgings, Rings & Bars in the following Low Alloy Grades

AISI 4130,

AISI 4140,

AISI 4145,

AISI 4330,

AISI 4340 / 817M40 (T),

AISI 8630,

AISI 8630M,

F22,

S355

NICKEL ALLOYS

We supply Shaped Forgings, Rings & Bars in the following Nickel Alloy Grades

625 INCONEL,

718 INCONEL,

725 INCONEL,

925 INCONEL,

MONEL 400,

MONEL K500

STAINLESS STEELS

We supply Shaped Forgings, Rings & Bars in the following Stainless Grades

F51 DUPLEX,

F53 & F55 SUPER DUPLEX,

304 STAINLESS,

316 STAINLESS,

F347 STAINLESS,

410 STAINLESS,

420 STAINLESS,

F6NM,

17-4 PH